100 ah lithium ion battery is 12 v battery industry packaging companies to use science and technology and physical knowledge of series-parallel assembled, has wide application field, In our daily communication field and audio-visual equipment, electronic equipment, industrial instruments, medical devices, etc., more common, the following 12v 100ah lithium ion battery market use observation is summarized:

1, Solar lighting industry: such as solar street lights, solar insecticidal lamps, solar garden lights, solar energy storage power supplies.

2, Electric toy industry: such as electric remote control cars, electric robots, etc.

3, Activity lighting industry: such as hernia lamps, high-power LED flashlights, diving lights, searchlights, etc.

4, Field of power tools: such as electric screwdriver, electric drill, electric scissors, etc.

5, Bluetooth audio, amplifier field.

6, handheld vacuum cleaner.

7, LED lamps and various electronic instruments and meters.

type:

Lithium-ion batteries can be divided into cylindrical, square and polymer types according to their appearance. Cylindrical lithium-ion batteries are commonly found in consumer electronics, such as mobile phones and laptops. Square lithium-ion batteries are suitable for electric vehicles, electric bicycles and other fields. Polymer lithium-ion batteries have a higher energy density and lower weight, and are commonly found in mobile devices, drones, and so on.

:

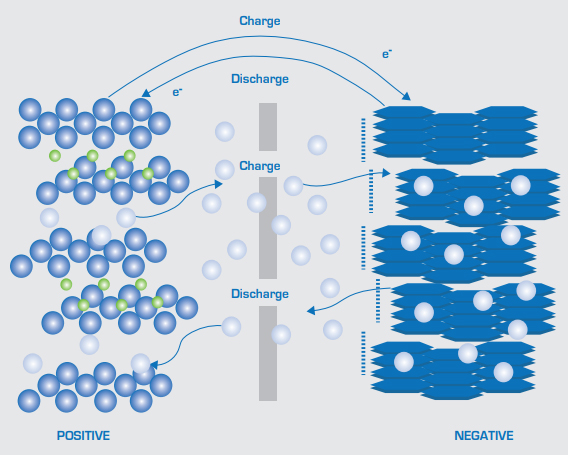

lithium ion battery is mainly composed of cathode materials, anode materials, electrolytes and the diaphragm. The positive electrode material is the most critical component of the lithium-ion battery, responsible for storing and releasing energy, and commonly used positive electrode materials include ternary materials, lithium iron phosphate and so on. The anode material is mainly carbon material, such as graphite. The electrolyte is responsible for conducting lithium ions, and the diaphragm prevents short circuits inside the battery.

production process:

The production process of lithium-ion batteries includes positive electrode material preparation, negative electrode material preparation, electrolyte and diaphragm preparation, battery assembly and formation steps. Among them, formation is a key step in the production of lithium-ion batteries, which fully activates the active substances inside the battery through the first charge and discharge, so as to achieve the best electrochemical performance.

12V 100Ah lithium-ion battery as an efficient, environmentally friendly and reliable energy storage solution, has a wide range of application prospects in various fields. With the continuous expansion of the market and the continuous progress of technology, it is playing a more and more important role in modern society, and its future in the rise of green energy and the continuous enhancement of environmental awareness, it can be said that the development potential is huge. In terms of the market, with the increasing attention to renewable energy and environmental protection, as well as the rapid development of electronic equipment, power tools and other fields, the market demand for 12V 100Ah lithium-ion batteries has shown a growing trend. Especially in the fields of solar lighting, electric toys, and activity lighting, its market demand is particularly strong. In addition, with the progress of science and technology and the reduction of costs, the application of 12V 100Ah lithium-ion batteries in communication equipment, audio-visual equipment, electronic equipment and other fields will also be further expanded.