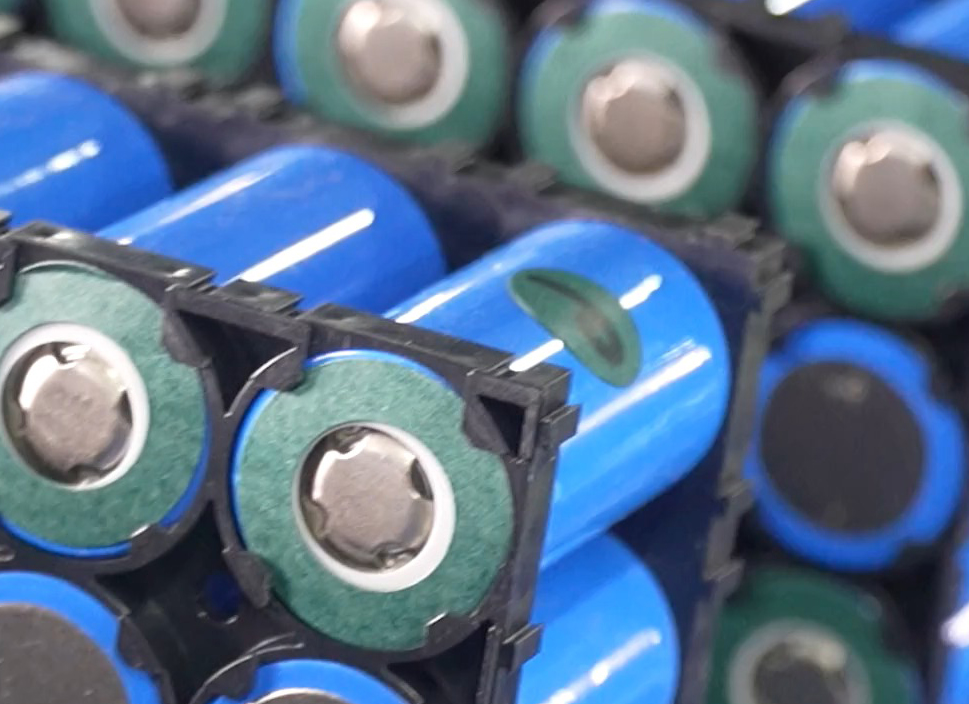

Li-ion battery module is a kind of power unit that combines multiple Li-ion batteries in series and parallel by means of conductive connectors, which is fixed in the designed position through process and structure, and synergistically performs the function of charging, discharging and storing of electric energy. The basic role of lithium battery module is to connect, fix and provide safety protection. Its structural design must support, fix and protect the electric core, and at the same time meet the requirements of mechanical strength, electrical performance, thermal performance and fault handling ability.

[ Detailed production steps of lithium battery module ]

1. Raw material procurement and inspection

The first step in the production of Li-ion battery modules is to ensure the quality of all raw materials. This includes cells, diaphragms, aluminum foils, adhesive tapes and so on. Raw materials need to undergo strict quality inspection, and be categorized and stored according to quality requirements for subsequent processing.

2. Core assembly

Core assembly is a key step in the production process. First of all, the electric core is combined with diaphragm, aluminum foil and other components, and then it is wound and welded to finally form a battery module. In this process, attention needs to be paid to safety issues to avoid accidents such as short circuit and fire.

3. Assembly and quality control

After the cell assembly is completed, the next step is assembly and quality inspection. This process includes welding, laminating, sealing and other steps to ensure that the quality of the battery module meets the requirements. At the same time, each battery module is individually inspected and tested to ensure its performance and safety.

4. Segmentation test

Partitioning test is to charge and discharge the battery modules separately to verify their performance and reliability. This process requires the use of standard test equipment and technical means, such as constant current charge/discharge meters, AC resistance testers and so on. Special attention should be paid to safety issues during the testing process to prevent accidents.

5. Comprehensive test

After completing the typing test, all battery modules need to be tested comprehensively. This includes capacity test, cycle life test, temperature cycle test and many other tests to fully verify the performance and reliability of the battery module. These tests ensure that the battery modules can meet customer requirements and standards.

6. Product Confirmation and Shipment

After comprehensive testing, each battery module needs to be confirmed and shipped. This includes appearance inspection, function test and packaging inspection to ensure that the product meets customer requirements and standards. At the same time, each batch of products is tracked, recorded and managed so that problems can be identified and solved in a timely manner. Final quality check and acceptance are also required before shipment to ensure product quality and stability.

7. Production line debugging and optimization

Before formal production, the entire production line needs to be debugged and optimized to ensure that all aspects of coordination and production efficiency. This includes equipment commissioning, process optimization, staff training and other aspects. Adequate commissioning and optimization is the key to ensure the stable operation of the production line and product quality consistency.

8. Quality control and traceability system

To ensure product quality and safety, it is crucial to establish a complete quality control and traceability system. This system covers raw material procurement, production process control, product testing and inspection, after-sales service, etc., which can timely detect and solve quality problems and improve product quality and reliability.

9. Safety and environmental protection measures

Lithium battery module PACK production line involves dangerous operations such as cell assembly and welding, so strict safety and environmental protection measures must be taken. This includes the development of operating procedures, safety training, and the construction of protective facilities to ensure employee safety and health, while avoiding environmental pollution.

10. Continuous improvement and innovation

Market demand and technology continue to develop, lithium battery module PACK production line also needs continuous improvement and innovation. This includes technological innovation, process optimization, equipment updating and other aspects, in order to adapt to market demand and technological development, and improve product competitiveness and market share.

11. Equipment maintenance and upkeep

The equipment of the production line requires regular maintenance and upkeep to ensure normal operation and productivity. This includes equipment cleaning, lubrication, inspection and repair to extend equipment life and reduce failure rate.

12. Employee training and management

Operators of the lithium battery module PACK production line need to receive professional training and management to ensure that they can properly operate the equipment and execute the process. This includes safety training, operating procedures development, performance appraisal, etc., to improve the skill level and efficiency of employees and avoid operational errors.

13. Supply chain management and coordination

The production line requires close coordination and management with suppliers, customers and other parties to ensure the smooth running of raw material purchasing, production planning and product quality. This includes supplier evaluation, order management, logistics coordination and other aspects to ensure efficient production and consistent product quality.

Through the above steps, the production process of lithium battery modules not only ensures product quality and safety, but also meets the market demand for high-performance, high-safety and long-life battery systems through continuous improvement and innovation. With the rapid development of new energy vehicles and energy storage market, the production technology of lithium battery module is also progressing, which lays a solid foundation for the sustainable development in the future.