Communication sealed lead-acid batteries, or VRLA batteries for short, are a power solution designed for communication equipment and systems. This type of battery was born in the 1970s, and with the advancement of science and technology and the development of the industry, it has been widely used in UPS, telecommunication equipment, mobile communication equipment, computers and other fields. The core feature of Communication sealed lead-acid battery is its sealing. It adopts a fully sealed design, which ensures that the battery will not leak electrolyte during charging and discharging and will not produce acid mist, thus avoiding the problems of corroding equipment and polluting the environment. In addition, the VRLA battery has a valve that can control the internal gas pressure, and this design enables the battery to operate in a safe and stable state.

From a technical point of view, sealed lead-acid batteries for communication use adopt the cathode absorption sealing principle. In the late charging stage of the battery, the oxygen generated on the positive plate diffuses to the negative electrode through the spacer, reacts with the lead on the negative electrode and absorbs it, forming a closed reactive oxygen composite cycle. This design makes the battery have the characteristics of sealing without acid overflow and acid seepage, and also reduces the battery's own discharge rate, prolonging the battery's float charging service life. Communication sealed lead-acid battery also has the advantages of high efficiency gas absorption, very low self-discharge rate, long service life of deep cycle. High-efficiency gas absorption enables the battery to utilize the gas more effectively during the charging and discharging process, which improves the energy conversion efficiency of the battery. The extremely low self-discharge rate means that the battery can still maintain a high level of power when not in use for a long period of time, providing a stable power supply for communication equipment. Long deep cycle life means the battery can withstand more charge/discharge cycles, reducing the frequency and cost of battery replacement for users.

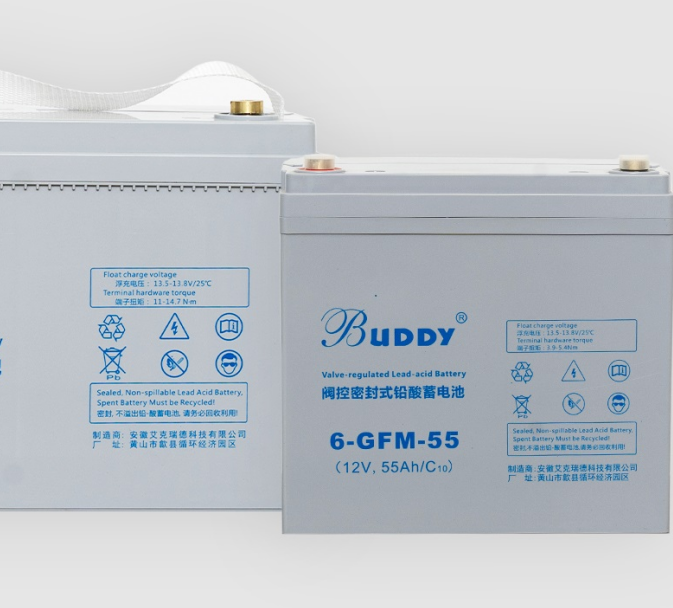

1, 6GFM (ordinary AGM type) series battery specifications and technical parameters

Battery type | rated voltage(V) | Rated capacity (A.h) | Overall dimensions(mm) | |||

10h | elder | widths | height | Total Height | ||

6-GFM-24 | 12 | 24 | 165 | 125 | 173 | 173 |

6-GFM-38 | 12 | 38 | 197 | 166 | 173 | 173 |

6-GFM-50 | 12 | 50 | 260 | 134 | 204 | 210 |

6-GFM-65 | 12 | 65 | 350 | 165 | 173 | 173 |

6-GFM-90 | 12 | 90 | 330 | 172 | 215 | 221 |

6-GFM-100 | 12 | 100 | 407 | 173 | 208 | 232 |

6-GFM-120 | 12 | 120 | 407 | 173 | 208 | 232 |

6-GFM-150 | 12 | 150 | 480 | 170 | 239 | 239 |

6-GFM-200 | 12 | 200 | 522 | 239 | 220 | 226 |

2、The working principle of lead storage battery

Lead storage batteries within the anode (PbO2) and cathode (Pb) immersed in the electrolyte (dilute sulfuric acid), between the two poles will produce 2V of electricity, which is based on the principle of lead storage batteries, by charging and discharging, the cathode and electrolyte that will occur in the following changes:

(Anode) (Electrolyte) (Cathode)

PbO2 + 2H2SO4 + Pb ---> PbSO4 + 2H2O + PbSO4 (discharge reaction)

(Lead peroxide) (Sulfuric acid) (Spongy lead)

(Anode) (Electrolyte) (Cathode)

PbSO4 + 2H2O + PbSO4 ----> PbO2 + 2H2SO4 + Pb (charging reaction)

(Lead Sulfate) (Water) (Lead Sulfate)

3、Lead-acid battery main technical process characteristics

3.1 The battery is tightly assembled to effectively prevent the active substance from falling off. Extend the service life of the battery.

3.2 High-efficiency gas internal recombination, sealing reaction efficiency can reach more than 98%. Minimal water loss. No need to add electrolyte or ionized water during the whole life.

3.3 The plate grid is made of special lead-calcium-high-tin alloy, which is more corrosion-resistant and has good charging acceptance ability. Small self-discharge. It makes the storage performance and usage performance of the battery better.

3.4 Adopt safe and reliable exhaust valve. Safer and more reliable use. Avoid explosion hazards caused by sparks.

3.5 The scientific rib structure greatly reduces the internal resistance of the battery. Make the current distribution more uniform. Better discharge performance.

3.6 Multi-layer labyrinth sealing technology, to ensure that the battery without seepage. No belly expansion phenomenon.

3.7 Adopt accurate grouping and control method, so that the consistency performance between battery and battery, between battery pole group and pole group is more superior.

3.8 Special electrolyte additives to prevent the battery lead dendrite short circuit and storage passivation.

3.9 Special internal resistance, voltage and battery capacity grouping equipment is adopted, with excellent battery group equalization and open circuit voltage difference ≤20mV.

4、Superiority of lead-acid battery

Good charging and discharging performance

Strong rechargeability after deep discharge, the battery capacity recovery rate is ≥99% after 21 days of continuous discharge with fixed resistance.

★ Long service life

Adopting Japan's advanced technology formula and process design, good service life.

★ Safe and reliable performance

Special structure of the electro-hydraulic method, fluorocarbon rubber exhaust valve, quantitative and effective acid filling, and higher sealing performance. The battery has no liquid leakage. Green environmental protection without pollution, safe use without worries.

★ Good environmental adaptability, high and low temperature resistance.

Adaptable to use in the environment of -30℃~55℃, except for the reverse buckle, can be installed in any direction, not subject to space constraints.

5、Product technical characteristics

5.1 Product implementation standards

IEC 60896-21 2004 Test Methods for Valve Regulated Stationary Lead-Acid Batteries

IEC 60896-22 2004 Requirements for Valve-regulated Stationary Lead-acid Battery

GB/T 19638.1-2014 Technical Conditions for Stationary Valve Regulated Lead-acid Battery

YD/T 799-2010 Valve Regulated Sealed Lead-Acid Battery for Telecommunication Applications

5.2 Operation control technical parameters (single battery)

Maximum charging current: 0.25C10

Discharge termination voltage: 10.80V

Float charging voltage: 13.35V~13.80V (charging temperature compensation factor: ±0.18mV/°C)

Constant charging voltage: 13.80V~14.40V (charging temperature compensation coefficient: ±0.24mV/°C).

6、Performance technical index

6.1 The battery can be used in the environment of -30℃~55℃, humidity less than 95% and altitude less than 3000 meters, and the floating life is more than 8 years in 25℃ environment.

6.2 The battery is tested according to the standard, 80% of the depth of discharge ≥ 600 times.

6.3 The battery is tested according to the standard, sealing reaction efficiency ≥ 96%.

6.4 Storage battery is tested according to the standard, monthly self-discharge rate ≤3%.

6.5 The open valve pressure of the battery is 10~35Kpa, and the closed valve pressure is 5~30Kpa.

6.6 The deviation range between the actual internal resistance value of the battery and the standard internal resistance value of the battery is located between -10%~+10%.

6.7 The open circuit voltage difference of the battery is ≤100mv after the fully charged battery has stood for 24 hours.

6.8 The battery is tested under 3I10A current standard, and the voltage drop of the connection strip between the batteries is ≤8mv.

6.9 After the battery is fully charged and left to stand for 90 days, its charge retention capacity is ≥90%.

7、Lead-acid batteries applicable range and environmental conditions

7.1 Suitable for telecommunication, electric power and UPS as well as energy storage system.

7.2 Temperature: -40~+60℃ conditions can be used normally.

7.3 Humidity: ≤95%.

7.4 Seismic capacity: horizontal acceleration ≥ 0.3, vertical acceleration ≥ 0.15.

7.5 Altitude: ≤3000m

In the field of communication, sealed lead-acid batteries for communication play a vital role. It can not only provide stable power supply for communication equipment, but also ensure that communication equipment can continue to work in emergency situations such as power outages, to ensure the continuity and stability of communication. In addition, sealed lead-acid batteries for communication also play an important role in the field of solar energy system, emergency lighting system, security system and medical equipment. Sealed lead-acid batteries for communication are a kind of efficient, stable and reliable power solution, providing solid power protection for communication equipment and systems.